Package Quicklinks:

![]()

Questions? Fill out the form or call/text/WhatsApp Kameron Anderson @ 403-819-3906

![]()

Questions? Fill out the form or call/text/WhatsApp Kameron Anderson @ 403-819-3906

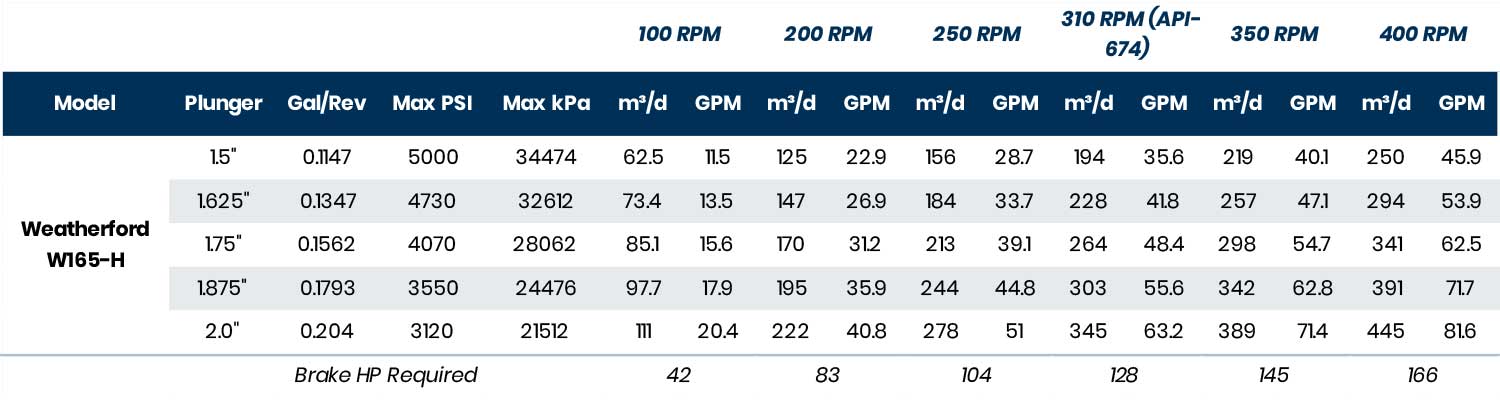

Five identical pump packages – 2 are NEW/never used and the other three all had approximately 2 years total run time each. They utilize a Weatherford W165H Triplex pump driven by a NORD gearbox and 150HP electric motor. On the one end of the skid, there is a 160HP VFD in a separate room from the pump. Designed for easy transport there are also optional 60” x 10’ separator buildings (image shown below) that were designed to work in conjunction with these and can be purchased in conjunction if required for your application.

View the optionally paired 60” x 10’ Sour 675psi Horizontal Jet Pump Separator Packages

![]()

403-819-3906

Explore this package in rich detail through a virtual walkthrough below.

Gable Style Building

Download a Crusader branded feature sheet or for brokers, an unbranded feature sheet for you to share with your customer network.

Drawings will be available shortly. Contact us for requests.

Click on the “Additional information” tab above to see at a glance details for this package.

| Condition | 5 Currently Available – 2 NEW / 3 USED |

|---|---|

| Pump | Weatherford W165H |

| Motor and VFD | 150HP TEFC 1783RPM Motor w/ 160HP 240Amp VFD on skid (separate room) |

| Location | Grande Prairie, AB |

| Availability | Immediate |

| Service | Sour |

| Piping | 3” 300# suction; 2” 2500# RJ discharge |

| Electrical | Fully wired to JB’s |

| Shipping Dimensions | 25’9” L x 10’10” W x 10’8” H |