Description

Equipment Overview

Just refurbished! Extremely flexible, yet simple in design, this 200hp Quintuplex pump package is fully reconditioned, ready to go (just pick your plungers), and comes with the same warranty you’d get by buying new! Built for sour service, it features internally coated pipe, 7 bag SS filter, 200HP WEG Motor, ANSI style charge pump, and an aluminum bronze medium pressure fluid end. Full drawings and QA included. Located in Nisku at PACE Hauling, they are ready to load and haul this unit for you right away. Contact us to discuss for pricing, drawings, and to discuss your application.

360º Virtual Tour

Explore this package in rich detail through a virtual walkthrough below.

Main Pumps, Motors & Assemblies

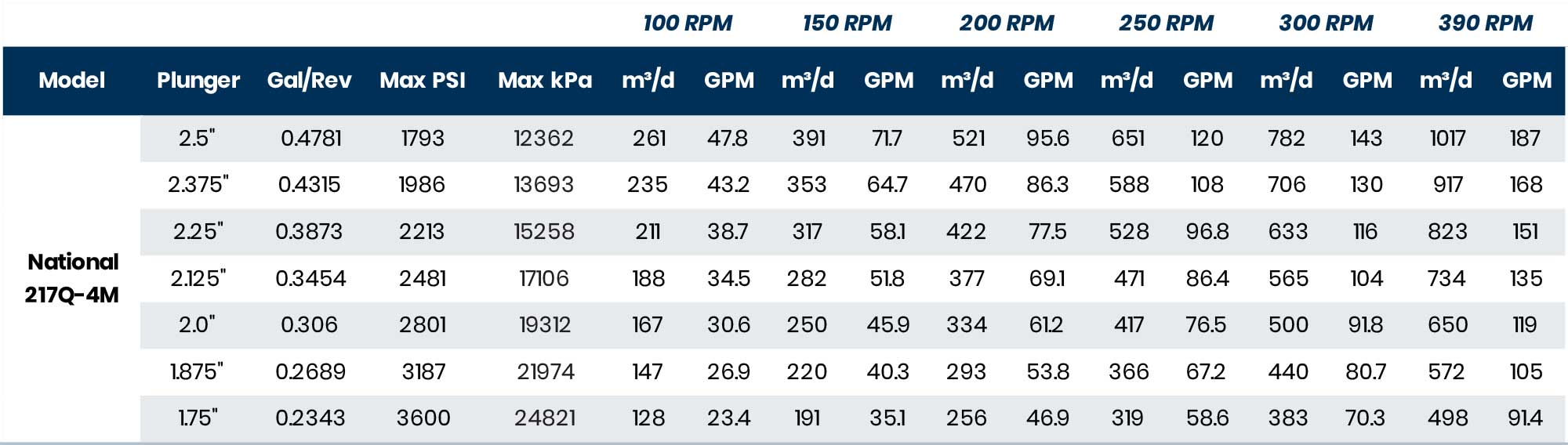

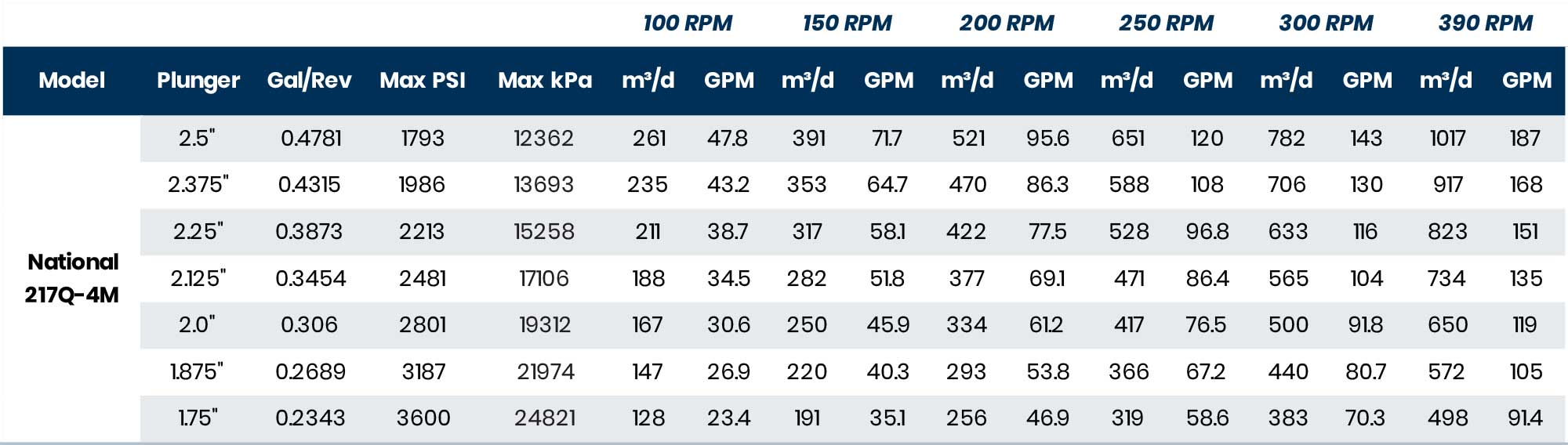

One (1) REMANUFACTURED Wheatley-Q4240M (NOV-Q217-4M) Quintuplex Pump (P-200)

- Client choice of plungers included

- 4” 150# FF Suction Connections

- 2” 900/1500# FF Discharge Connections

- SS Stuffing boxes

- AR Style Suction/Discharge Valves

- Low Oil Level Switch

- High Vibration Switch

- 12 Month (NEW) Warranty

- Equipped with 2HP Auxiliary power end lubrication system which is superior to splash lubrication for power end longevity and allows for slow speed operation (<150RPM) If future application requires.

One (1) NEW 200 HP Motor (M-200)

- WEG

- TEFC, 1200 RPM

- Roller Bering drive end

- Invertor duty rated for Constant Torque

- 460/3/60 VAC

- 449T Frame

- Belt drive system and safety guard

One (1) 5 Feed Packing Lubricator (L-200)

- Mounted on Pump and Belt driven

- Fed from One 200 Liter Day Tank on stand

One (1) USED Suction Pulsation Stabilizers (PD-100)

One (1) USED Discharge Pulsation Stabilizers (PD-200)

- 300 cu inch

- 2” 1500# RF

- 300 cu/in

- 4” 150# RF

One (1) USED Discharge Pulsation Stabilizers (PD-200)

Charge Pump & Accessories

One (1) Eagle ANSI Charge Pump (P-100)

- 3 x 1.5 x 8 A100S ANSI centrifugal Pump

- C.S. Fluid End and Impeller

- Mechanical Seal

- Rated at 240 GPM at 65 PSI

One (1) NEW 10 HP Charge Pump Motor (M-100)

- 10 HP, TECO 3450 RPM Motor

- TEFC

- 460/3/60 VAC

- 254 TC Frame

Filter Vessel

One (1) NEW 7 Bag filter vessel assemblies (F-100)

- 2100m3/day capacity

- Stainless Steel Construction

- Qty 7 Stainless Steel P2 size Baskets

- MAWP 150 PSI

- MAWT -20/+100 F

- 6” 150# RF connections in/out

- 2” NPT drain connection

- AB/BC/SK CRN Registration

Instrumentation & Controls

FE-200 One (1) 2” x 2” EZ-IN Nu-Flo Turbine

FQIT-200 One (1) Halliburton MC-II Totalizer, Battery powered

VSH-200 One (1) Murphy VS2-EX High Vibration switch

LSLL-200 One (1) Murphy EL150-EX Low Pump Lube Oil Level switch

PI-100 One (1) 4” Bottom Mount, 0-15 PSI, Liquid Filled Pressure Gauge

PI-200 One (1) 4” Bottom Mount, 0-100 PSI, Liquid Filled Pressure Gauge

PI-300 One (1) 4″ Bottom Mount 0-100 PSI Liquid Filled Pressure Gauge

PI-400 One (1) 4” Bottom Mount, 0-5000 PSI, Liquid Filled Pressure Gauge

DPI-100 One (1) WGI Differential Pressure gauge on filter vessel

PSL-100 One (1) CCS Dual Snap Low suction pressure switch (set falling 20 PSI)

PSL-200 One (1) CCS Dual Snap Low discharge pressure switch (set falling 1000psi)

PSH-200 One (1) CCS Dual Snap High Discharge pressure switch (set rising TBA)

PSL-201 One (1) CCS Dual snap Low aux lube oil pressure on main pump

PSV-200 One (1) 2″ MNPT x 2” FNPT BAIRD762-7601 Pressure Relief Valve (set at TBA)

DT-200 One (1) 200-liter Day Tank for Plunger Lubricator

PCV-100 One (1) KIMRAY 2″ 1500 # RF Startup Bypass control valve

EY-300 One (1) ASCO Solenoid for Startup bypass valve on/off control

Process Piping & Valves

Suction Piping: 150# RF Design (NEW)

- 150 PSIG MAWP, 1/8” CA, 10% RT, Sch 40

- 6” 150# ANSI RF Piping and Valves from skid edge to 4″ basket strainers, isolation valve and charge pump suction.

- 1-1/2” and 4″ Discharge from Charge Pump to Filter Inlet c/w 4″ Isolation Valves

- 6” Filter Discharge w/ 4” Isolation Valves to 4” Pump Suction

- Internally coated with Devoe 253

Discharge Piping: 900# RF Design (NEW)

- 3” and 2″ 900# ANSI RF Piping and Valves

- 2” 900# ANSI RF Start-up Bypass/PSV Connections

- 3” 900# Isolation and Check valve on each main pump discharge piping

- Startup Bypass and PSV discharge Into suction before charge pump

- Internally coated with Devoe 253

Note** Package can be operated at 1500# pressure with simply changing out 2 spools on the discharge

Drain Piping

- Filter drain are threaded 2” SCH 80 and routed to drain sump

- Basket Strainer drain is threaded 1”

- P-200 stuffing box drains are routed to drain sump

Notes

- Piping is Built to ASME B31.3 Latest Edition

- Fabricated in ABSA Approved Facility

- 10% X-Ray, PWHT Included

- All Piping is blasted, primed and painted with warm grey enamel

- All pipe/fittings/bolting/gasket materials to be standard temperature (-20 to 100F)

One (1) Skid and Building Assembly

- One (1) 14’ x 22′ Structural Steel Skid assembly, winchable

- W12 steel main members

- W18 steel crossmembers

- 4 Lifting Lugs on side of skid assembly

- ¼” Checker Plate Floor

- 1.5” high containment lip around charge pump/filter drains into drain sump

- Drain sump with 2” drain piped to 2” NPT at skid edge

One (1) 14’ x 22′ x 9’ Eve height Self Framing Gable Style Building

- Painted Exterior w/ Fluted Aluminum Interior Liner

- One (1) Double Man Doors c/w Panic Hardware, IWG Window

- One (1) Single Man Doors c/w Panic Hardware, IWG Window

- Two (2) 36” x 36” Windows with sliders and screen

- One (1) Exhaust fan (high mounted in gable end) with weighted louvers w/ OA switch

- One (1) Manual Louver Inlet (Low mounted)

- One (1) Hazloc 15kW Electric Heater 480/3/60 VAC w/ built in thermostat

Electrical

- Two (2) Interior lights with switch at single man door

- One (1) Exterior light with switch at double door

- One (1) 110 VAC electrical outlet by double door

- Three (3) HOA switches for main pump. charge pump and aux lube pump

- One (1) OA switch for exhaust fan

- One (1) High Vibration switch on main pump

- One (1) Low oil level switch on main pump

- One (1) Pressure switch low for auxiliary lube on main pump

- Two (2) ESD Switches, 1-exterior/ 1-Interior

- Two (2) Junction boxes on exterior building 110 VAC/Analog/Discrete

Documentation

Operation, Parts, Service and QA Manual provided with package c/w:

- Pump Curves

- Installation and Operation manual

- Parts and service Manual for equipment

- Data sheets for all equipment in package

- QA includes standard Alberta AQP Package

- AB-83 for Piping/Filter Vessel

- U1A for filter vessel

- Spool dwg’s

- GA, P&ID, Structural Dwgs

![]()

![]()